Summarized from Storey and Delatte, Lessons from the Collapse of the Schoharie Creek Bridge, Proceedings of the 3rd ASCE Forensics Congress, October 19 – 21, 2003, San Diego, California

Introduction

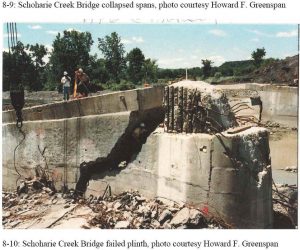

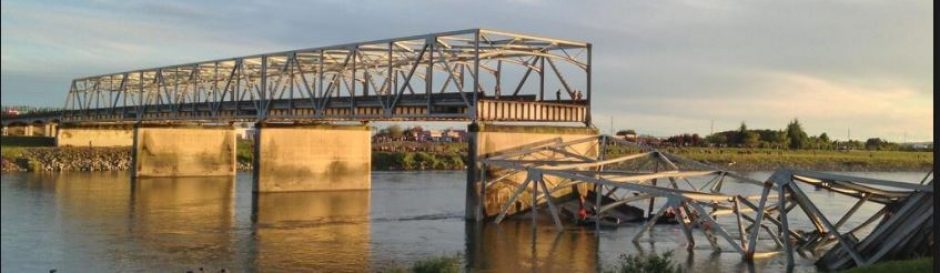

The Schoharie Creek Bridge collapsed on the morning of April 5, 1987, after three decades of service. The collapse of pier three caused two spans to fall into the flooded creek. Five vehicles fell into the river, and ten occupants died.

Bridges across waterways must be designed structurally not only to carry their own weight and traffic loads but also to resist the hydraulic forces imposed by rivers and other bodies of water. Moreover, the construction of the bridge abutments and piers alters the rivers flow, and may lead to new patterns of erosion and deposition. The collapse of the Schoharie Creek Bridge illustrates the importance of designing bridge piers to resist scour. The case also illustrates the importance of the inspection and maintenance of bridges.

Design and Construction

The Schoharie Creek Bridge was one of the several bridges constructed by the New York State Thruway Authority (NYSTA) for a 900 km (559-mile) superhighway across New York State in the early 1950s. The bridge was situated northwest of Albany in the Mohawk Valley (WJE Associates, 1987).

The 1949 edition of the American Association of State Highway Officials (AASHO now the American Association of State Highway and Transportation Officials, AASHTO) Standard Specifications for Highway Bridges was used for the design of the Schoharie Creek Bridge. The preliminary design for the bridge was contracted out to Madigan-Hyland Consulting Engineers (WJE Associates, 1987).

The design firm developed two designs for the crossing of the Schoharie Creek. The preliminary designs were similar except for the lengths of spans, one 183 meters (600 feet) and the other 165 meters (540 feet). Both plans placed two piers on shallow footings in the Schoharie Creek and two piers on the creek banks to support the structure.

The New York State Department of Public Works (DPW), later named the New York State Department of Transportation (NYSDOT), approved the 165 meter (540-foot) bridge for the crossing of the Schoharie Creek. The final design was submitted in January 1952 and consisted of five simply supported spans with nominal lengths of 30.5, 33.5, 36.6, 33.5, and 30.5 meters (100, 110, 120, 110 and 100 feet). Concrete pier frames supported the bridge spans along with abutments at each end (figure 1).

Figure 1. Pier Section

The pier frames were constructed of two slightly tapered columns and tie beams. The columns were fixed within a lightly reinforced plinth, which was positioned on a shallow reinforced spread footing. The spread footing was to be protected by a layer of dry riprap. The superstructure was made up of two longitudinal main girders with transverse floor beams. The skeleton of the 200 mm (eight-inch) thick bridge deck was comprised of steel stringers (WJE Associates, 1987). A plan of the bridge spans is shown in figure 2.

Figure 2. Schematic plan of bridge (after Collapse,1987)

he construction contract for the bridge was awarded to B. Perini and Sons, Inc. on February 11, 1953, and construction began shortly thereafter. Madigan-Hyland Consulting Engineers performed construction inspection for the bridge in conjunction with DPW. The majority of the construction was completed and the bridge was opened to partial traffic during the summer of 1954. The Schoharie Creek Bridge was fully completed soon after October of 1954 (WJE Associates, 1987). Nearly a year later, the bridge successfully survived a 100 year flood, but the damage from the October 16, 1955 flood may have had a bearing on the collapse three decades later (NTSB, 1988).

The as-built plans did not reflect the true condition of the bridge. They showed that sheet piling had been left in place to protect the piers. However, it had been removed after construction (WJE Associates, 1987, NTSB, 1988).

Pier Modifications

Shortly after construction was completed, in the spring and summer of 1955, the Schoharie Creek Bridge pier plinths (shown in figure 1) began to form vertical cracks. The cracks ranged from 3 to 5 mm (1/8 to 3/16 inches) in width and the locations of the cracks varied from pier to pier (WJE Associates, 1987). The cracks occurred due to the high tensile stresses in the concrete plinth. The plinth could not resist the bending stresses between the two columns. The original designs called for reinforcement to be placed in the bottom portion of the plinth only since designers had confidence that the concrete in tension could resist the bending stresses without reinforcement.

It was later determined that the upper portion of the pier plinths had a tensile stress of 1.4 MPa (200 psi) and there should have been more than 39,000 square mm upwards of 60 square inches of steel in the upper face of the plinth (WJE Associates, 1987). In 1957, plinth reinforcement was added to each of the four piers to correct the problem of vertical cracking.

The plinth may be seen as an upside down uniformly loaded beam, with the soil bearing pressure providing the uniform loading and the two columns acting as supports. It becomes obvious that the top of the plinth represents the tension face of the beam and requires reinforcement. However, to be properly anchored the tension reinforcement must be extended past the supports in this case, into the columns (NTSB, 1988). Obviously, this was not done, and it would have been difficult to extend the reinforcement through the columns without replacing the columns. Ironically, because the added plinth reinforcement was not adequately anchored, it may have contributed to the brittle and sudden nature of the subsequent collapse, by supporting the plinth until most of it had been undermined (WJE Associates, 1987, Thornton-Tomasetti, P. C., 1987).

There were several other problems that occurred shortly after the completion of the bridge. Inspectors noticed that the expansion bearings were out-of-plumb, roadway approach slabs had settled, roadway drainage was poor, and the supporting material for west embankment dry stone pavement was deficient. All of the problems mentioned and other minor problems were corrected by fall of 1957 (WJE Associates, 1987).

The Collapse

The Schoharie Creek Bridge collapsed on the morning of April 5, 1987, during the spring flood (Boorstin, 1987, Thornton et al., 1988). Rainfall totaling 150 mm (6 inches) combined with snowmelt to produce an estimated 50-year flood (WJE Associates, 1987).

The collapse was initiated by the toppling of pier three, which caused the progressive collapse of spans three and four into the flooded creek. The piers and spans are shown in Figure 2. One car and one tractor-semitrailer were on the bridge when it collapsed. Before the road could be blocked off, three more cars fell into the gap. The drivers of the other vehicles were probably too close to the bridge to stop in time when it fell. Over the next three weeks, nine bodies were recovered. One was never found. (NTSB, 1988).

Pier two and span two fell ninety minutes after span three dropped, and pier one and span one shifted two hours after that (Thornton-Tomasetti, P. C., 1987). The NTSB suggested that pier two collapsed because the wreckage of pier three and the two spans partially blocked the river, redirecting the water to pier two and increasing the stream velocity (NTSB, 1988). The missing span and the floodwaters may be seen at the following websites:

| Scour Critical Bridges (2002) https://www.nationalbridgeinventory.com/scour_critical_bridges.htm> | |

| Hudson International – includes an animation of the collapse of the second span https://members.aol.com/higrp/bridge.htm | |

| MRCE website – Schoharie Creek Thruway Bridge (2002) https://www.mrce.com/pages/projects/1987-3.shtml |

Six days later, a large section of the Mill Point Bridge located about 5 km (3 miles) upstream of the Schoharie Creek Bridge collapsed. Fortunately, the bridge had been closed since the flood because NYSDOT feared that its foundation had also been eroded (WJE Associates, 1987).

Causes of Failure

Two teams investigated the Schoharie Creek Bridge failure Wiss, Janney, Elstner (WJE) Associates, Inc. with Mueser Rutledge Consulting Engineers investigated for the NYSTA, and Thornton-Tomasetti, P.C. investigated for the New York State Disaster Preparedness Commission. The teams cooperated, and the chief role of Thornton-Tomasetti, P.C. was to review WJEs work. A number of other firms assisted in the investigation (Bridge Collapse @ 2002, Schoharie Creek Thruway Bridge @ 2002). A cofferdam was constructed around the failed piers and the site was dewatered and excavated, both to aid the investigation and the construction of the replacement bridge (WJE Associates, 1987).

Each of the teams prepared a report as to the cause of the failure, and they similarly concluded that the collapse of the Schoharie Creek Bridge was due to the extensive scour under pier three. Scour is defined as the removal of sediment from a streambed caused by the erosive action of flowing water (Palmer and Turkiyyah, 1999). The vulnerability of scouring under pier three was affected by four important factors (Thornton-Tomasetti, P. C., 1987):

� The shallow footings used, bearing on soil, could be undermined.Therefore the depth of which the footings was not enough to take them below the probable limit of sour.

� The foundation of pier 3 was bearing on the erodable soil. Layers of gravel, sand, and silt, interbedded with folded and tilted till allowed high-velocity floodwaters to penetrate the bearing stratum.

� The as-built footing excavations and backfill could not resist scour. The area left around the footing due to excavation was backfilled with erodable soil and topped off with dry riprap, in turn rather than being backfilled with riprap stone to the entire depth of the excavation as design plans specified.

� Riprap protection, inspection, and maintenance were inadequate.

The process of scouring under the piers began shortly after the bridge was built. In 1955, the bridge footings experienced floodwater flows unanticipated in the design of the bridge, a 100-year flood, and it is believed that the majority of the scouring energy was dissipated into moving the original riprap layer from around the footings. Once the backfill had been exposed, the years of peak flows removed the backfill material, and the backfill , in turn, as replaced by sediment settling into the scoured holes (WJE Associates, 1987).

The 1955 flood had an estimated flow of 2.17 million liters per second (76,500 cfs). The 1987 flood had an estimated flow of 1.8 million liters per second (63,000 cfs) and an estimated velocity of 4.6 meters per second (15 fps). However, after the 1955 flood, berms were constructed upstream, and the velocity at the bridge may have been the same as the 1955 flood. Furthermore, the riprap placed at construction had probably been washed away during the 1955 flood and had not been replaced (WJE Associates, 1987).

This process continued until so much material was removed that there was a loss of support capacity (Shepherd and Frost, 1995). The upstream end of pier 3 fell into a scour hole approximately 3 meters (9 feet) deep (NTSB, 1988). It was estimated that approximately 7.5 to 9 meters (25 to 30 feet) of the pier was undermined (WJE Associates, 1987).

The damage due to scour is shown at the Hudson International website (https://members.aol.com/higrp/bridge.htm). The bridge design originally called for leaving the sheet piles (which were used to keep water out of the excavation area during construction) around the piers (Levy and Salvadori 1992). The specified riprap would then fill the area left between the pier footings and sheeting.

Unfortunately, the sheet piles were not left in place. Possibly, they could have prevented the scour altogether. Levy and Salvadori note (p. 146) that in the contract issued in 1980 for maintenance work, all reference to new stone riprap had been deleted by a nonengineer state employee who decided, after viewing the site from shore, that it was unnecessary. The NTSB also noted this incident (NTSB, 1988).

The riprap was also too light. The specification called for riprap with 50 % of the stones heavier than 1.3 kN (300 pounds) and the remainder between 0.44 and 1.3 kN (100 to 300 pounds). However, the investigators found that riprap weights of 4.4 to 6.7 kN (1,000 to 1,500 pounds) should have been specified (WJE Associates, 1987).

Although the main cause of the bridge failure was scour, there were several other items considered during the investigation of the collapse. These items include the design of the superstructure, quality of materials and construction, inspection and maintenance of superstructure, inspection, and maintenance of piers above streambed, and inspections performed using the guidelines available at the time of inspections. These items did not contribute to the collapse of the Schoharie Creek Bridge (Thornton-Tomasetti, P. C., 1987).

Thornton-Tomasetti found six items that aggravated the tendency for scour (pp. 3-5, Thornton-Tomasetti, P. C., 1987):

� The flood was greater than that anticipated by the designers and followed the 1955 flood and others that had disturbed the riprap.

� A curve in the river upstream of the bridge directed a higher-velocity flow toward pier 3.

� Drift material caught against the piers directed water downward at the base of pier 3.

� Berms built in 1963 directed floodwaters under the bridge.

� An embankment west of the creek channel increased flood velocities.

� The Mohawk River dam downstream was set for winter conditions and was 3 meters (10 feet) lower than in the 1955 flood, increasing the hydraulic gradient.

Furthermore, Thornton-Tomasetti found a number of other factors that contributed to the severity of the collapse (pp. 5-6, Thornton-Tomasetti, P. C., 1987):

� The bridge bearings allowed the spans to lift or slide off of the concrete piers.

� The simple spans were not redundant.

� The lightly reinforced concrete piers did not have enough ductility to permit frame action.

� The plinth reinforcement stopped the hinge action of the plinth cracks. Therefore, instead of dropping slowly into the scour hole, the plinth cracked suddenly.

The first two elements were common practice when the bridge was designed in the 1950s.

The National Transportation Safety Board conducted its own investigation and concluded that the probable cause of the accident was a failure to maintain riprap. As contributing factors, they pointed to ambiguous construction plans and specifications, an inadequate NYSTA bridge inspection program, and inadequate oversight by the NYSDOT and FHWA (NTSB, 1988).

Scour and Countermeasures

Scour removes material through three mechanisms (Thornton et al., 1988, Palmer and Turkiyyah, 1999). These are:

- Long term aggredation or degradation, the change in channel bottom elevation that occurs through normal erosion and deposition of material in the river bed. Clearly, the degradation is of concern from a bridge safety standpoint.

- Contraction scour when the stream width is narrowed by natural processes or bridge abutment and pier construction. By the continuity equation Q = Av (where Q = flowrate, A = cross-sectional area, and v = velocity), if the channel cross-sectional area decreases then the velocity must increase, resulting in an additional lowering of the channel bottom elevation.

- Local scour occurs when the flow is obstructed by a pier or abutment placed in the floodplain. Vortexes that form at the pier or abutment remove stream bed material. (p. 62, Huber, 1991).

Clearly, at a bridge pier, all three processes occur and are additive. Because the last two mechanisms occur only after the bridge has been constructed, the extent of potential scour may be difficult to estimate in advance.

Scour may be countered by riprap, by supporting piers on piles, my providing cofferdams around piers, and through other measures. The key is an adequate prediction of the hydraulic forces that occur during powerful floods. The analysis should also include the effects of potential land use changes upstream, such as increases in runoff from development and associated paving.

Lessons Learned

The NTSB suggested a number of ways that the disaster could have been prevented, or that the loss of life could have been reduced. The thruway bridge, like other bridges on the Schoharie Creek, could have been supported on piles, which would have resisted scour. The AASHO 1949 provisions were unclear on whether piles were required for this bridge. In the absence of the piles, leaving the sheet piling in place and providing enough riprap would have helped protect the pier. However, the quantity estimates provided to the contractor by the design engineer did not have enough sheet piling or riprap for pier protection. The use of continuous spans, rather than simple spans, would have provided redundancy once pier three failed, and perhaps allowed for the redistribution of forces between the spans. Also, the plinth reinforcement added after the bridge construction was not anchored in the columns (NTSB, 1988). The reinforcement does not cross the crack in the plinth of pier 3, shown in figure 7.

However, the key lesson pointed out by the NTSB was operational, not technical. It is important for bridge owners to identify the critical features that can lead to the collapse of a bridge and to ensure that those critical features are inspected frequently and adequately (NTSB, 1988).

Technical Aspects. The WJE Associates report notes that bridges must be designed for hydraulic, geotechnical, and structural effects. Of the three, only the geotechnical design, relying on the support strength of the glacial till, was satisfactory (WJE Associates, 1987).

Bridge inspections play a major role in evaluating the superstructure and substructure for deterioration to determine if maintenance is required. Bridge inspections in New York State were required on an annual/biannual basis. The state also required diver inspections of the underwater structures every five years (Levy and Salvadori, 1992).

Although the Schoharie Creek Bridge had been inspected annually or biennially since 1968, an underwater inspection of the piers footings had never been performed. The bridge was scheduled for an underwater inspection in 1987, but the bridge collapsed before the inspection took place (NTSB, 1988).

The Thornton-Tomasetti report notes where riprap is used to prevent scour, inspection and restoration of protective riprap should be performed after every significant flood to avoid progressive damage, and the replacement stones used should be heavier than those which were observed to shift. (p. 20, Thornton-Tomasetti, 1987).

Due to the collapse of the Schoharie Creek Bridge and other bridges failing in a similar manner, bridge inspectors were further trained to recognize scour potential by examining and comparing any changes in the conditions from previous inspections (Huber, 1991). Scouring failures also sparked the much-needed research for detecting scour potential.

The Catalog And Expert Evaluation of Scour Risk And River Stability (CAESAR) system was developed by the University of Washington for evaluating scour through computer technology and for aiding bridge inspectors during the assessment process. The report documenting the program discusses the necessity of identifying screamers,those indicators of imminent collapse that require an agency to close a bridge (Palmer and Turkiyyah, 1999).

Educational Aspects. The bridge failures of the past demonstrate how important bridge inspection is for management and safety of the transportation network. The failures also emphasize how important it is to design footings deep enough to avoid loss of support capacity due to scour (Shepherd, 1995).

Changes to Engineering and Management Practices

When the bridge was built, the tools of the day were not adequate for predicting scour. While the bridge was in service, the inspection procedures used were not sufficient to detect the scour. Since the collapse of the Schoharie Creek Bridge, important advances have been made. A study conducted in 1989 revealed that 494 bridges failed during the years 1951 and 1988 as a result of hydraulic conditions, primarily due to scouring (Huber, 1991).

Summary and Conclusions

The collapse of the Schoharie Creek Bridge was an important event in the development of bridge design and inspection procedures. It is important to accurately predict the effects of scouring, and to design bridges to resist those effects. Lessons learned to include:

- Proper selection of a critical storm for the design of bridges crossing water.

- The need for regular inspections of the superstructure, substructure, and underwater features of the bridge.

- The importance of adequate erosion protection around piers and abutments susceptible to scour.

Print References:

Boorstin, Robert O. (1987). Bridge Collapses on the Thruway, Trapping Vehicles, Volume CXXXVI, No. 47,101, The New York Times, April 6, 1987.

Huber, Frank. (1991). Update: Bridge Scour. Civil Engineering, ASCE, Vol. 61, No. 9, pp 62-63, September 1991.

Levy, Matthys and Salvadori, Mario (1992). Why Buildings Fall Down. W.W. Norton and Company, New York, New York.

National Transportation Safety Board (NTSB). (1988). Collapse of New York Thruway (1-90) Bridge over the Schoharie Creek, near Amsterdam, New York, April 5, 1987. Highway Accident Report: NTSB/HAR-88/02, Washington, D.C.

Palmer, R., and Turkiyyah, G. (1999). CAESAR: An Expert System for Evaluation of Scour and Stream Stability.National Cooperative Highway Research Program (NCHRP) Report 426, Washington D. C

Shepherd, Robin, and Frost, J. David (1995). Failures in Civil Engineering: Structural, Foundation and Geoenvironmental Case Studies. American Society of Civil Engineers, New York, New York.

Thornton, C. H., Tomasetti, R. L., and Joseph, L. M. (1988). Lessons From Schoharie Creek, Civil Engineering, Vol. 58, No.5, pp. 46-49, May 1988.

Thornton-Tomasetti, P. C. (1987) Overview Report Investigation of the New York State Thruway Schoharie Creek Bridge Collapse. Prepared for: New York State Disaster Preparedness Commission, December.

Wiss, Janney, Elstner Associates, Inc., and Mueser Rutledge Consulting Engineers (1987) Collapse of Thruway Bridge at Schoharie Creek, Final Report, Prepared for: New York State Thruway Authority, November.

Web References:

Bridge Collapse (2002). <https://members.aol.com/higrp/bridge.htm>

Schoharie Creek Thruway Bridge (2002)

<https://www.mrce.com/pages/projects/1987-3.shtml>

Scour at Schoharie Creek at Interstate 90 (west pier) (2002) <https://ny.water.usgs.gov/projects/scour/fig5.html>

Scour Critical Bridges (2002) <https://www.nationalbridgeinventory.com/scour_critical_bridges.htm>

Ten Years Since Major Bridge Collapse (1997) <https://ny.usgs.gov/projects/scour/>

Illustrations from Chapters 5 and 8 of the book Beyond Failure: Forensic Case Studies for Civil Engineers, Delatte, Norbert J., ASCE Press.