Overall Structure of Linear Motion Modules

Linear Motion Systems are designed with a variety of different components, the main components of a linear motion system include:

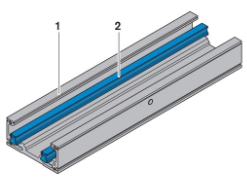

1. Guideway – Serves as the main body of a linear motion system, the guideway is made up of the frame and linear guides.

-

-

- Frame – The frame of a linear motion system is a load-bearing profile which gives the linear motion system its structure and strength.

- Guides – The guides give the linear motion system its power transmission and accuracy. For linear motion systems, Bosch provides three types of linear guides:

- Ball Rail Systems: These systems usually have a higher load capacity than either the cam roller guide or linear bushings. Ball rail systems also have more preload possibilities, higher rigidity, and better travel accuracy than the other two guideway types.

- Cam Roller Guides: Cam roller guides have a higher linear speed and are typically quieter than the other two types of guideways. However, cam roller guides also have lower load capacities than the other two types.

- Linear Bushings: Have average load capacities, rigidity and travel accuracy, but are usually the least expensive out of the three types.

-

2. Carriage/Runner Block – The carriage and runner block are the two components that are moved from one point to another. The carriage is driven by the drive unit and guided by the guide unit in order to move between the two points. The runner block serves as a table which sits upon the carriage; in situations where cargo moves between the two points, the runner block bears most of the weight of the cargo.

3. Linear Drive Units – Linear Drive Units serve as a method to transform electromechanical (or pneumatic) energy to linear kinetic energy. Some linear drive units require assistance from a motor in order to completely transform electrical energy to linear mechanical energy. Bosch sells the following linear drive units:

-

-

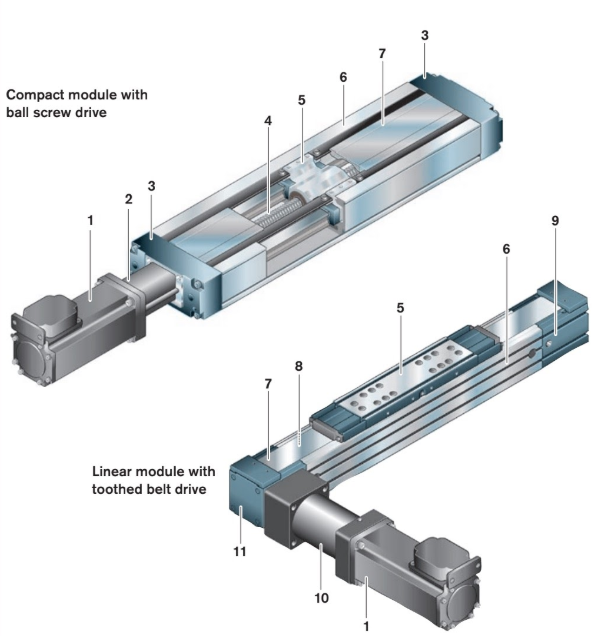

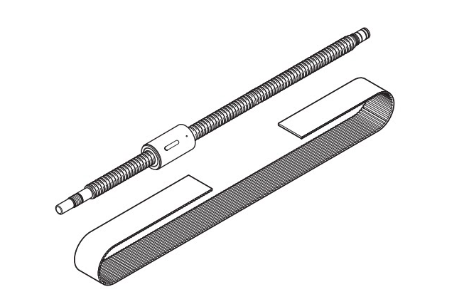

- Ball Screw Assemblies: Suitable for feed tasks that require a lot of precision. This type of drive unit usually requires some other form of drive unit in the form of a motor.

- Toothed Belts: Suitable for tasks that require a lot of dynamic capabilities. This type of drive unit usually requires a motor in order to transmit motion.

- The toothed belt is made out of abrasion-resistant polyurethane that is reinforced by high-strength steel cords. The toothed belt is operated by a pulley combined with the drive end and tension end enclosures.

- Linear Motors: Can be used to replace the drive unit of a linear motion system. The thrust is generated directly at the carriage, therefore they usually do not require any additional drive element to transmit the thrust.

-

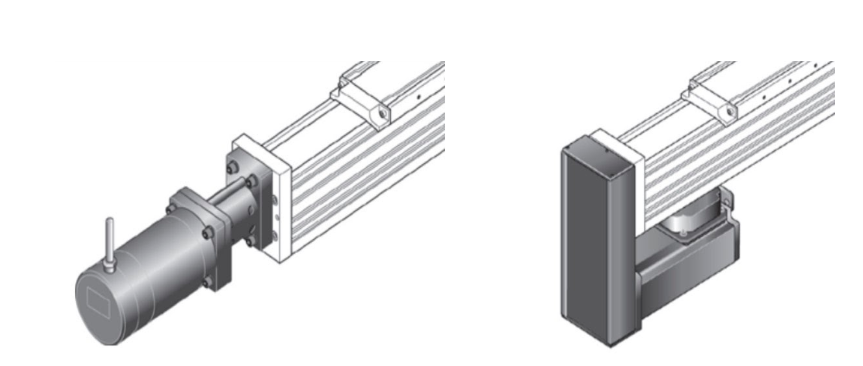

4. Rotary Motors –Rotary Motors are used as an additional drive unit for linear motion systems with Ball Screw Assemblies or Toothed Belts. Bosch gives the option to use their own supply of rotary motors, which include the following motor types:

-

- Servo Motors

- Three-Phase Motors

- Stepper Motors

5. End Blocks – End-Blocks are components that close up the ends of linear motion systems. End blocks are made in accordance to the motion system’s drive unit.

6. Switches – Most linear motion systems include switches in order to determine the position of the carriage on the system. Among the switches that Bosch sells, they are classified as either limit switches, reference switches or both.

-

- Limit Switches are switches that help to determine the ends of the linear motion system. These switches cut off the current if the carriage moves over it. This is to avoid damage to the carriage, and any attached peripherals, that can come from the carriage overshooting the end position.

- Reference Switches can determine the approximate distance of the runner block from the sensor. The reason these switch types are called reference switches is because in case of a power outage, the position of these sensors can be used as a reference to help the carriage move back to its starting location.

7. Other Features – The following features are considered “optional” for Bosch’s linear motion systems:

-

-

- Screw Supports

- Connection Plates

- Clamping Fixtures

- Position Measuring Systems

-

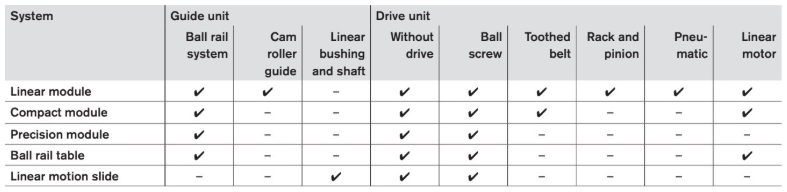

Types of Modules

- Linear Module: This type of linear module is the standard type of module that Bosch makes. It can come with any of the possible drive units and guideways available from Bosch’s inventory.

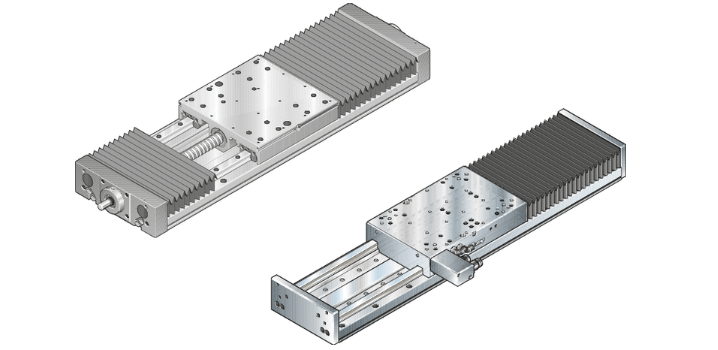

- Compact Module: These types of Linear Modules are characterized by their high power density. All of the compact module types are equipped with two ball rail systems and can come with one or two carriages depending on the situation. Another characteristic of compact modules is their (relatively) flat construction. For all types and sizes that Bosch sells the width to height ratio is approximately 2:1.

- Precision Module: These types of Linear Modules are modules with ball rail systems and ball screw drive. They are very compact, highly rigid, and very precise. They are very useful in drive, transport, and positioning tasks.

- Function Module: This module is single-rail or dual-rail versions, as well as with belt drive or Ball Screw Assembly

- Feed Module: Feed Modules are modules that are built to optimize between high precision and high force transmission. The system has a low moved system mass, which makes them perfect for vertical movement along the z-axis.

- Omega Module: The omega modules are made with a special type of compact precision aluminum profile with a ball rail system. The module, unlike the other types, has the lubrication port on the side of the carriage. The omega modules are driven by a toothed belt drive in order to maximize the linear speeds of the module.

Other Types of Linear Motion Systems

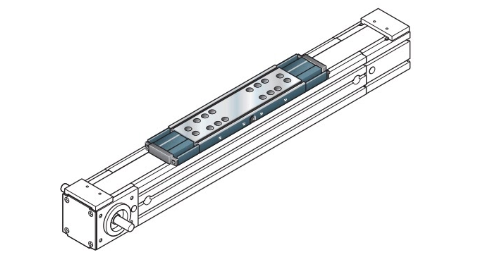

Ball Rail Table

- Ball Rail Table: The ball rail tables are linear modules that contain two ball rail systems spaced apart from each other. The spacing between the two rails allows the module to be able to resist very high torsional moments. The table plate is built out of four runner blocks, with two runner blocks per ball rail system. Therefore the module is also able to withstand high amounts of load and high longitudinal moments.

Combinationality of Linear Motion Systems

Even though any combination of the above can give valid linear motion systems, there are only a few that produce linear motion systems that are sensible and cost efficient.

The table below gives the combinations allowable for certain linear motion systems. This table is from a handbook from Bosch from 2007, so the table also includes the combinations of modules with drive systems that are no longer sold by Bosch; mainly the rack and pinion drive and the pneumatic drives.