Bosch Rexroth Profile Rail System PDF Guide (Section 3)

Introduction to Profiled Rail Systems

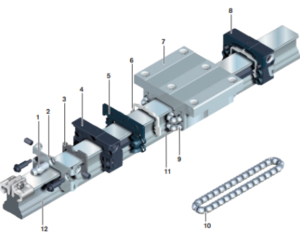

Profiled rail systems are the guides of choice for applications requiring especially high precision, low maintenance, low wear and low friction, as well as highly accurate positioning. Profile rails are essentially “roller skates” that help guide heavy loads accurately. Profiled rail systems consist of a runner block and a guide rail. Runner blocks are mounted on the guide rail and are connected to your machine components. Guide rails are mounted as a base for the machine components are are generally fixed to a flat surface.

Theory

This section describes the structural design of a rail system, the types of rail systems (Ball Rail, Roller Rail, and Cam Roller Guides, general calculations, friction reduction techniques, and uses in integrated measuring systems.

Naming Conventions

Naming conventions are important for any design process as many variations of products exist. Some of the profile rail system abbreviations discussed are the Ball Rail System, Miniature Ball Rail System, eLINE Ball Rail System, Roller Rail System, and Cam Roller Guides. Naming conventions are also important for distinguishing dimensions of products. Some dimensions to be designated are width, length, height, and ball guide sizing.

Sizes, Designs, and Characteristics

As a follow-up to the naming conventions page, sizes and system characteristics are very important for the design process. Using this page, designers can find the best fit size and runner block style to best fit their needs.

Mounting

Mounting of profile rails is very important as this will greatly affect the performance, accuracy, and life of the product. Different mounting techniques, products, and time to mount rails are defined in this section.

Product Selection

Product selection is important to the design process as different designs are used for specific applications. This section describes how an engineer or designer may go about selecting the right profile rail.

Benefits of using Profiled Rail Systems

- Profile rails have an extremely long life expectancy and require minimal maintenance (oiling and lubrication are necessary)

- Create extremely precise conditions for machines

- Can hold large loads while also moving with great speed and accuracy

Relevant Profiled Rail Systems Videos

Pricing

If this is a product that can be useful for your Senior Design Project, please contact a Bosch Rexroth representative here for more information. Pricing can be determined on a case-by-case basis.

Linear Motion Technology Handbook. Linear Motion Technology Handbook, Bosch Rexroth, 2007.