Results

Intermediate-Scale Tests

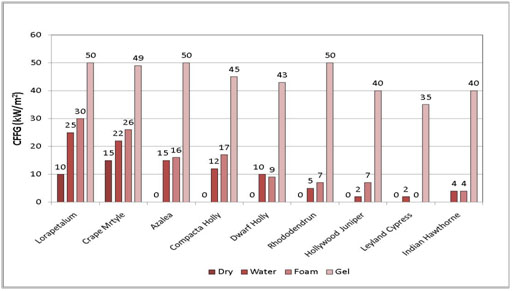

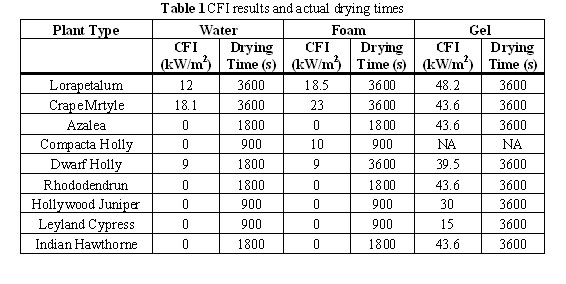

The CFFG determined for the plant specimens tested without a wetting agent and with wetting agent application without additional drying after the wetting agent application are shown in Figure 1. The CFFGs determined for the plant specimens tested with wetting agent application with additional drying after the wetting agent application (accelerated drying) are shown in Figure 3. Some drying times needed to be reduced. The actual drying times are given in Table 1.

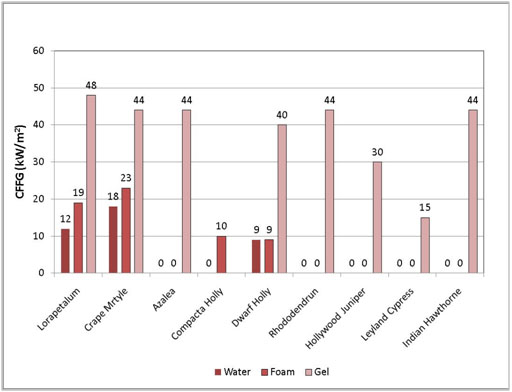

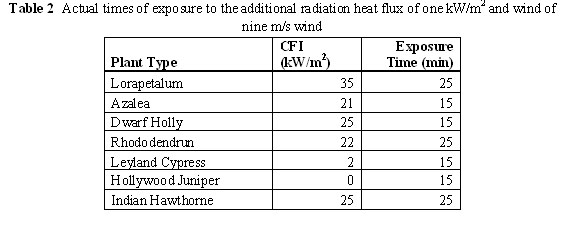

The CFFGs determined for the plant specimens tested with wetting agent application and with the accelerated drying are shown in Figure 3. The drying times needed to be reduced from the originally planned exposure time of 60 minutes. The actual drying times are given in Table 2. The CFFG for Crape Myrtle could not be determined. Only the data with gel used as the wetting agent are available. The other wetting agents did not provide any additional protection of the plant under the accelerated drying conditions.

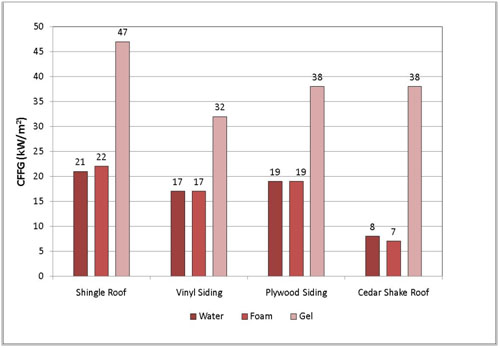

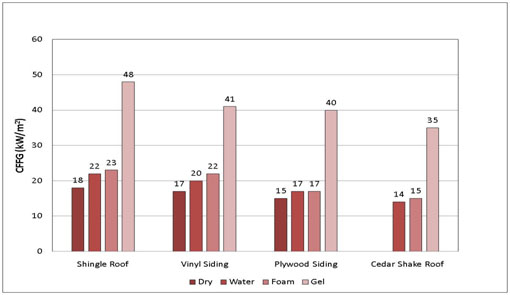

The CFFG determined for the external wall and roof assemblies tested without a wetting agent and with wetting agent application without additional drying after the wetting agent application are shown in Figure 6.

The CFFGs determined for the external wall and roof assemblies tested with wetting agent application with additional drying after the wetting agent application are shown in Figure 5. The drying times for the vinyl siding using water and foam as wetting agents needed to be reduced to 15 minutes.

Figure 1 CFFG for plants tested without additional drying after wetting agent application

Figure 2 CFFG for plants tested with additional drying after wetting agent application

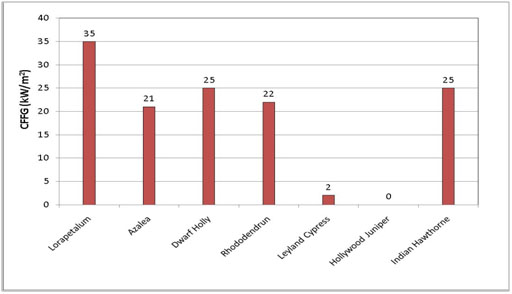

Figure 3 CFFG for the plants exposed to the additional radiation heat flux of one kW/m2 and nine m/s wind

Figure 4 CFFG for external wall and roof assemblies tested without additional drying after wetting agent application (the dry value is not provided since the values are too scattered probably because the fire retardant on the material was not uniformly distributed)

Figure 4 CFFG for external wall and roof assemblies tested without additional drying after wetting agent application (the dry value is not provided since the values are too scattered probably because the fire retardant on the material was not uniformly distributed)

The CFFG determined for the exterior wall and roof assemblies tested with wetting agent application and with the application of accelerated drying are shown in Figure 8. The drying times needed to be reduced from the originally planned exposure time of 60 minutes for the plywood siding wall assembly to 25 minutes. Only the data with gel used as the wetting agent are available. The other wetting agents did not provide any additional protection of the plant under the accelerated drying conditions.

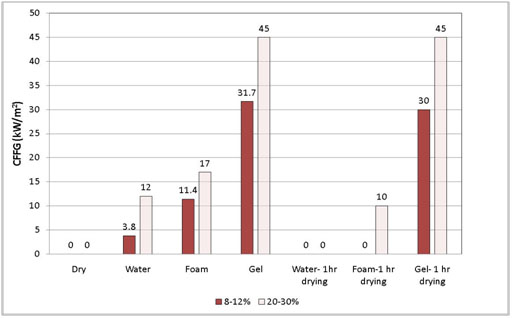

It was observed during this project that some plants dried relatively non-uniformly. The areas of the plants that were drier than other areas were easier to ignite and burned with more intensity. To determine what the worst case situation might have been, we decided to test one plant that was completely dried beyond its 25 % water content condition. The plant that was selected was a Compacta Holly. Its water content was about 10 %. This plant was selected because of its relatively large size and dense leaves and branches. The results of the tests on this completely dry plant are compared in Figure 9 to the results obtained on the same plant at about 25 % of water content. The CFI determinations were not performed for the accelerated drying condition.

Figure 5 CFFG for the external wall and roof assemblies tested with additional drying after wetting agent application

Figure 6 CFFG for the external wall and roof assemblies exposed to the additional radiation heat flux of one kW/m2 and nine m/s wind

Figure 7 CFI comparison of Compacta Holly between its water contents of 20-30% and at 8-12% (completely dry)

Full-Scale Tests

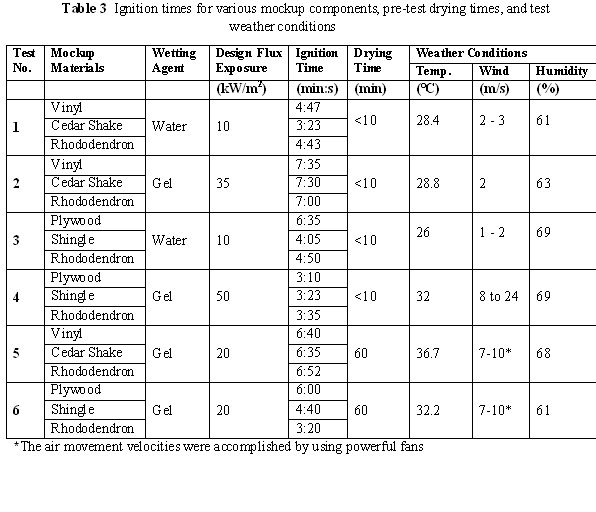

The ignition times for individual parts of the mockups and for the plants for Tests 1-6 are shown in Table 3. The table also contains the general test information and the weather information at the starts of the tests. Figures 8-13 show the flux measurements at the two mockup locations, and Figure 14 shows an example of the surface temperature measurement results.

Table 3 Ignition times for various mockup components, pre-test drying times, and test weather conditions

Summary of the Results

1. All the wetting agent untreated plants except for Lora Pedlum and Crape Myrtle ignited without any external radiation heat flux. The wall and roof specimen require external radiation in order to ignite in three minutes.

2. The effectiveness of water and foam is similar and minimal if it is applied more than 10 minutes before the application of external heat flux.

3. The accelerated drying conditions cause both the plants and the building elements to ignite without any external radiant flux (what is called ignition is actually flame spread or fire growth, which require lower heat fluxes for the initiation of the process in comparison to the actual ignition, which is accomplished by a relatively large flame in this project), probably because the equilibrium moisture contained in the specimens after conditioning is removed to a large extent.

4. Gel appears to be the only wetting agent that protects the plants and building materials from ignition in wildland urban interface fire conditions if it is applied at least one hour prior to the arrival of the fire front. Some plants and building materials require the gel to be applied at shorter times prior to the fire front.

5. A significant number of variables that cannot be controlled, and are related to the plants as well as the wetting agent application, introduce a certain level of uncertainty in the level of the radiant flux that the plants and the building materials can withstand.

6. If the radiation exposures are known, the results of this work can be used to design the protection of plants and buildings from wildfires.

7. The duration of radiant heat exposure used in this work is conservative, which might improve the likelihood that the plants and building materials in actual fires would not ignite during fire front passage.

8. Future work is required to better understand the ignition properties of accumulated ambers and the times of fire front passage for various fuel categories, weather conditions, and landscape conditions.

- The full-scale test results confirmed the intermediate scale results indicating that the intermediate scale testing can be used to determine the three-minute CFFG for landscaping plants and external building materials.

- Firefighting gel is very effective in preventing fire growth in WUI fire conditions. This result was confirmed when radiation exposure fluxes of up to 50 kW/m2 are present for up to three minutes, and occasional direct flame impingement occurs.

- The conditions studied in this work are limited to wildland fire effects on buildings, and not building to building fire spread.

- The results of this work can be used to design the protection of buildings from wildland fire exposures when the exposures are known.

References

[1] Cohen, J.D., Preventing Disaster: Home Ignitability in Wildland-Urban Interface, Journal of Forestry, March 2000.

[2] Ettlinger, M.G., Beall, F.C., Development of a laboratory protocol for fire performance of landscape plants, International Journal of Wildland Fire, 13, p. 479-488, 2004.

[3] Cohen, J.D., Butler, B.W., Modeling Potential Structure Ignitions from Flame Radiation Exposure with Implications for Wildland/Urban Interface Fire Management, Proceedings of 13th Fire and Forest Meteorology Conference, Lorne, Australia 1996.

[4] Leonard, J. and Bowditch, P. 2003, Findings of studies of houses damaged by bushfire in Australia, presented to Third International Wildland Fire Conference, Sydney, Australia, 3–6 October.

RECOMMENDATIONS

This research has shown fire-blocking gel to be significantly more effective than either water spray or type A foam in preventing fire ignition or growth on buildings in many realistic wildland-urban interface (WUI) fire conditions. Results also showed that the level of protection of the gel depends on the amount/thickness and uniformity of it application. However, only one gel was tested, limiting the impact this information can have in protecting landscaping plants, structures, and those protecting them from fire. Further research is needed that will expand current results by investigating all major gel products on the market to gauge thickness and uniformity of application and the effects of these parameters on their effectiveness.

Significant uncertainty related to the effectiveness of gels and increase the safety of firefighters and homeowners in WUI fire environments needs to be reduced. The uncertainty mainly related to the landscaping vegetation size, plant type and configuration, as well as to the wetting agent, especially gel application thickness, uniformity, and type needs to be further investigated. In particular the research with the following objectives is suggested:

- Investigate gel application techniques and gel properties[1] of various gel manufacturers in relation to uniformity of substrate coverage and maximum quantity of gels that can be applied on building siding and roofing products.

- Using comparable application techniques, compare the effectiveness in terms of the critical flux for ignition/flame spread of currently commercially available gels for fire protection on building siding and roofing products as described in [1].

- Investigate the uniformity of gel concentrate and water ratios using various applicators and application techniques recommended by manufacturers and used by firefighters and homeowners.

- Investigate the effectiveness of various gels when pre-applied at times longer than one hour.

- Determine optimal ratios of the gel concentrate and water to provide optimal amounts of the gel applied onto various substrates.

- Investigate to what extent dried gel can re-absorb water using different water spraying techniques.

- Provide guidance to firefighters and homeowners as to which product to choose, and how to apply it for optimum protection from ignition.

- Provide guidance to gel manufacturers to improve the application techniques for their products.

REFERENCE

- Urbas, J. and P. Desai, Effectiveness of Pre-Applied Wetting Agents in Prevention of Wildland Urban Interface Fires, Proceedings of the 12th International Fire Science and Engineering Conference (Interflam 2010), July 2010 in Nottingham, UK, Interscience Communications Ltd., July 2010.

[1] Gel properties related to toxicity will not be investigated in this proposed project.